Choosing the Right Electrical Enclosures for Your Industrial Needs

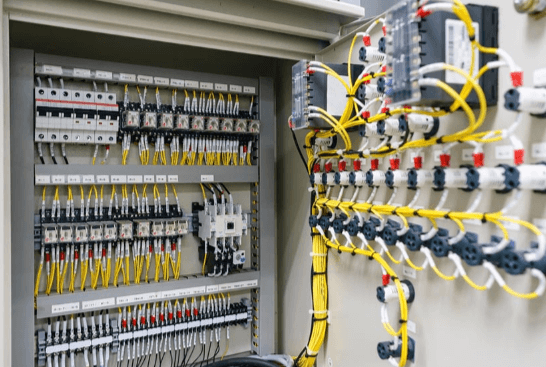

Electrical enclosures play a crucial role in protecting electrical equipment from environmental factors such as dust, moisture, and chemicals.

They are essential for ensuring the safety and reliability of electrical systems in industrial settings.

Choosing the right electrical enclosures for your specific industrial needs is important to ensure optimal performance and longevity of your equipment.

In this article, we will discuss the key factors to consider when selecting electrical enclosures for your industrial applications.

1. Environmental Conditions

One of the first considerations when choosing an electrical enclosure is the environmental conditions in which it will be placed. Different industrial settings have varying levels of exposure to dust, water, corrosive chemicals, and other contaminants.

Electrical Enclosures are designed to protect sensitive equipment from various environmental conditions, including moisture, dust, and extreme temperatures. These rugged enclosures ensure that electrical components remain safe and operational, even in harsh industrial environments or outdoor installations.

It is crucial to select an enclosure that offers the appropriate level of protection against these elements to prevent damage to the enclosed equipment. Factors such as the IP (Ingress Protection) rating, material of construction, and any additional features like cooling or heating systems should be taken into account.

For example, in a dusty environment, an enclosure with a high IP rating and gasketed seams would be necessary to keep the internal components clean and functioning properly. Similarly, in a wet or corrosive environment, a stainless steel or fiberglass enclosure with proper sealing would be required to prevent water ingress and corrosion.

2. Material Selection

The material of the enclosure plays a significant role in its performance and durability. Common materials used for electrical enclosures include stainless steel, aluminum, and polycarbonate. Stainless steel enclosures are ideal for harsh environments where corrosion resistance is essential. Aluminum enclosures are lightweight and cost-effective, making them suitable for a wide range of applications.

Polycarbonate enclosures are non-corrosive and provide excellent impact resistance. The choice of material for an electrical enclosure is crucial for ensuring its effectiveness and longevity. Stainless steel enclosures are perfect for environments prone to corrosion, offering exceptional durability and resistance.

On the other hand, aluminum enclosures are favored for their lightweight nature and cost-effectiveness, making them versatile for various uses.

Polycarbonate enclosures, known for their non-corrosive properties and superior impact resistance, are an excellent option for applications where durability is key.

Ultimately, selecting the right material for the enclosure is essential to guarantee optimal performance and longevity in different operating conditions.

3. Size and Configuration

When selecting an electrical enclosure, it is important to consider the size and configuration of the equipment that needs to be housed.

The enclosure should have adequate space to accommodate all components and allow for proper ventilation to prevent overheating. Additionally, the enclosure should be easily accessible for maintenance and inspection purposes.

It is also crucial to select an enclosure that offers protection against environmental factors such as water, dust, and corrosive substances, depending on the location and conditions of the installation.

The material of the enclosure should be chosen carefully to ensure durability and protection of the equipment inside. Finally, considering any specific requirements or regulations for the industry or application is essential to ensure the enclosure meets all necessary standards.

5. Hazardous Location Requirements

For industrial applications in hazardous locations where flammable gasses, vapors, or dust may be present, special considerations must be taken when selecting electrical enclosures.

Enclosures used in these environments must meet specific safety requirements to prevent ignition and ensure the protection of personnel and equipment.

When selecting electrical enclosures for industrial applications in hazardous locations where flammable gasses, vapors, or dust may be present, special considerations must be taken.

Enclosures used in these environments must meet specific safety requirements to prevent ignition and ensure the protection of personnel and equipment.

This includes features such as explosion-proof construction, sealed designs to prevent the entry of hazardous substances, and appropriate certification for use in hazardous areas.

It is crucial to carefully evaluate the requirements of the specific hazardous location and choose electrical enclosures that comply with the necessary standards to ensure safe operations.

Read also Common FAQs About Solar Installation in Homes

6. Customization and Accessories

Many manufacturers offer customization options and accessories for electrical enclosures to meet the unique needs of different industrial applications.

These may include mounting panels, cable management systems, cooling fans, and locks. It is important to consider these additional features to enhance the functionality and security of the enclosure.

Customization options and accessories for electrical enclosures play a crucial role in meeting the specific requirements of various industrial applications.

Manufacturers provide a range of accessories such as mounting panels, cable management systems, cooling fans, and locks to enhance the functionality and security of the enclosure.

These additional features not only improve the overall performance of the enclosure but also ensure the safety of the equipment housed within.

Therefore, it is essential to carefully consider these options to create a tailored solution that meets the unique needs of each application.

7. Compliance with Regulations

When choosing electrical enclosures for industrial use, it is essential to ensure compliance with relevant industry standards and regulations. Non-compliance can lead to safety hazards, fines, and legal liabilities.

Working with reputable manufacturers and suppliers who adhere to quality and safety standards is crucial to selecting compliant enclosures.

Additionally, it is important to consider the specific environmental conditions in which the electrical enclosures will be placed, such as exposure to moisture, dust, chemicals, or extreme temperatures.

Choosing enclosures with appropriate ingress protection (IP) ratings and material construction is vital to ensure the longevity and functionality of the equipment.

Regular maintenance and inspection of the enclosures are also necessary to identify any potential issues and prevent safety risks.

By prioritizing compliance, quality, and maintenance, industrial facilities can ensure the safety and efficiency of their electrical systems.

Conclusion

Choosing the right electrical enclosures for your industrial needs is a critical decision that can impact the performance, safety, and longevity of your electrical equipment. By considering factors such as environmental conditions, material selection, size and configuration, NEMA and IP ratings, hazardous location requirements, customization options, and regulatory compliance, you can ensure that you select enclosures that meet your specific requirements. Investing in high-quality enclosures will not only protect your equipment but also contribute to the overall efficiency and reliability of your industrial operations.