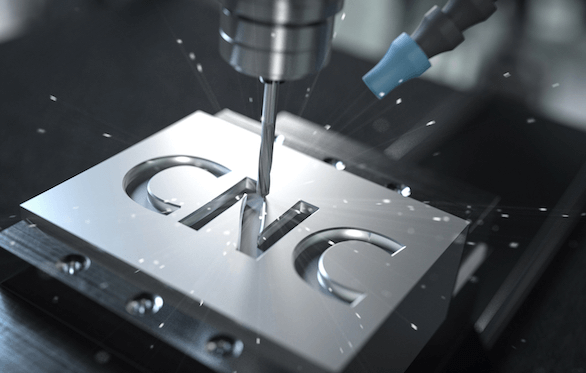

Exploring the Benefits of CNC Machining in Manufacturing

In the world of manufacturing, CNC (Computer Numerical Control) machining has revolutionized the way products are designed and produced. CNC machining is a manufacturing process that utilizes computerized controls to operate and manipulate machine tools, resulting in highly precise and efficient production. This technology has become increasingly popular across various industries due to its numerous benefits and advantages. In this article, we will explore the benefits of CNC machining in manufacturing.

Precision and Accuracy

One of the key benefits of CNC machining is its unparalleled precision and accuracy. The computerized controls used in CNC machines ensure that the cuts and movements are made with incredible accuracy, down to the smallest detail.

CNC machining services offer precise, automated manufacturing with high accuracy and repeatability, working with a wide range of materials like metals, plastics, and composites.

This level of precision is essential in manufacturing industries where even the slightest error can lead to costly defects and rejections. CNC machines can consistently produce high-quality, precise components, leading to improved product quality and customer satisfaction.

Increased Efficiency

CNC machining offers increased efficiency compared to traditional manual machining methods. Once a CNC machine is programmed with the design specifications, it can produce multiple identical components with minimal human intervention. This automation of the manufacturing process reduces the risk of human error, speeds up production times, and allows for 24/7 operation. As a result, manufacturers can increase their output while maintaining high levels of quality and consistency.

Cost-Effectiveness

While the initial investment in CNC machines may be higher than traditional machining equipment, the long-term cost-effectiveness of CNC machining is undeniable. CNC machines require less labor input, have lower maintenance costs, and can operate continuously without breaks or downtime. Additionally, the precision of CNC machining reduces material waste and minimizes the need for rework, saving manufacturers money in the long run. Overall, the cost savings associated with CNC machining make it a highly attractive option for manufacturers looking to optimize their production processes.

Flexibility and Versatility

CNC machining offers unparalleled flexibility and versatility in manufacturing. The same CNC machine can be used to produce a wide range of components simply by reprogramming it with different design specifications. This versatility allows manufacturers to quickly adapt to changing market demands and produce custom or complex parts with ease. CNC machines can also perform a variety of operations, including milling, turning, drilling, and grinding, making them suitable for a wide range of manufacturing applications.

Improved Safety

CNC machining improves safety in the manufacturing environment by reducing the risk of accidents and injuries associated with manual machining operations. With CNC machines, operators can control the entire manufacturing process from a safe distance, away from cutting tools and moving components. Additionally, CNC machines are equipped with safety features such as emergency stop buttons and protective enclosures to ensure the well-being of operators. By minimizing the need for manual intervention, CNC machining helps create a safer and more secure workplace for manufacturing personnel.

Enhanced Productivity

Another significant benefit of CNC machining is its ability to enhance productivity in manufacturing operations. CNC machines can work at a much faster pace than traditional machining methods, leading to increased productivity and shorter lead times. The automation of repetitive tasks allows operators to focus on more complex and value-added activities, further boosting overall productivity. By streamlining the production process and eliminating bottlenecks, CNC machining helps manufacturers meet deadlines, fulfill orders efficiently, and stay ahead of the competition.

Read also Sweet and Innocent: Capturing the Essence of Newborn Photography

Quality Control

Quality control is paramount in manufacturing, and CNC machining plays a crucial role in ensuring consistent quality standards are met. CNC machines are capable of producing highly precise and accurate components, leading to improved product quality and reliability. The computerized controls of CNC machines allow for real-time monitoring and adjustments, ensuring that each component meets the specified design criteria. This level of quality control helps manufacturers identify and rectify any issues early in the production process, minimizing the risk of defects and ensuring that only high-quality products reach the market.

Environmental Sustainability

CNC machining is also beneficial from an environmental sustainability standpoint. The precision of CNC machines results in minimal material waste, as they can cut with high accuracy and efficiency. Additionally, the automation of CNC machining reduces energy consumption compared to traditional machining methods, making it a more environmentally friendly option. By optimizing material usage, reducing energy consumption, and minimizing the impact on the environment, CNC machining contributes to sustainable manufacturing practices and helps companies align with environmental regulations and standards.

Conclusion

In conclusion, CNC machining offers a wide range of benefits that can significantly impact the manufacturing industry. From improved precision and efficiency to cost-effectiveness and environmental sustainability, CNC machining has become an essential technology for modern manufacturing processes. By investing in CNC machining, manufacturers can enhance their productivity, increase their competitiveness, and deliver high-quality products to meet the demands of today’s market. As technology continues to advance, CNC machining is poised to play an even greater role in shaping the future of manufacturing.